Heat Buffer with Solid Fuel Boiler

Heat buffers compatible with solid fuel boilers.

Most manufacturers of solid fuel boilers in their instructions recommend, even require:

- keeping the operating water temperature in the boiler in the range of 80-90ºC;

- ensuring a minimum return water temperature to the boiler of 55-65ºC;

- avoiding continuous operation of the boiler at efficiency levels below 40%, i.e., at low temperatures (these are apparent savings).

By using the NOEL heat buffer, we can maintain a constant boiler operating temperature of 70, 80, or even 90ºC, resulting in better fuel combustion. Under these conditions, the boiler is more efficient, maximally effective, and its lifespan is significantly extended. There is no phenomenon of flame or chimney fouling, as occurs at low operating temperatures (e.g., 40ºC on the boiler).

Economically with a heat buffer – up to 40% less fuel and a constant temperature in the system.

Working in conjunction with a solid fuel boiler, the heat buffer accumulates thermal energy and surplus heat. When the temperature in the buffer and on the boiler is equal (e.g., 80°C), the boiler stops working, entering an energy-saving mode until the temperature in the buffer drops below the set value. When heating the building or for hot water needs—assuming a tank with a coil is used—heat is extracted from the buffer.

It regulates the temperature in heating and hot water systems. In the event of a power outage or pump failure, it prevents the water in the boiler from boiling over (overheating the device). It has the ability to distribute heat to several heating circuits, ensuring a constant temperature and maintaining the desired temperature in all building rooms. By using the NOEL heat buffer, solid fuel boilers burn on average 30-40% less fuel, resulting in savings on fuel costs and time spent on frequent maintenance.

Remember about the safety of the heating installation with a solid fuel boiler and the proper selection of the buffer capacity for the boiler’s power.

Write to us, and we will select the appropriate model of the buffer with a coil for hot water for your solid fuel boiler.

Connection Schemes for Heat Buffer and Solid Fuel Boiler

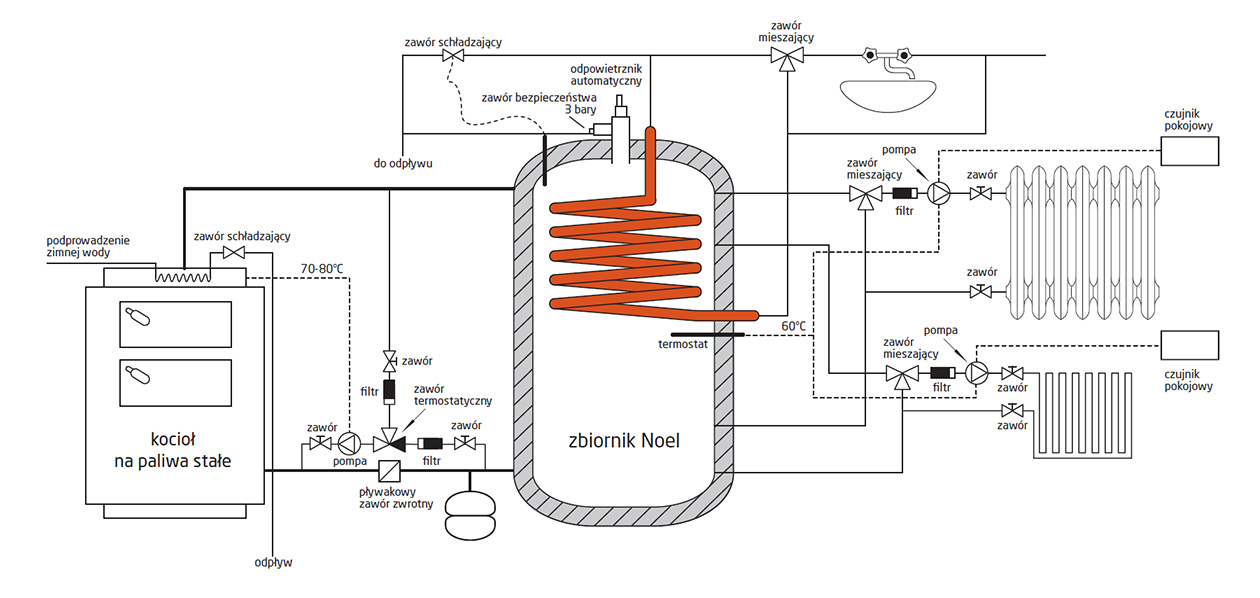

Connection Scheme for Solid Fuel Boiler

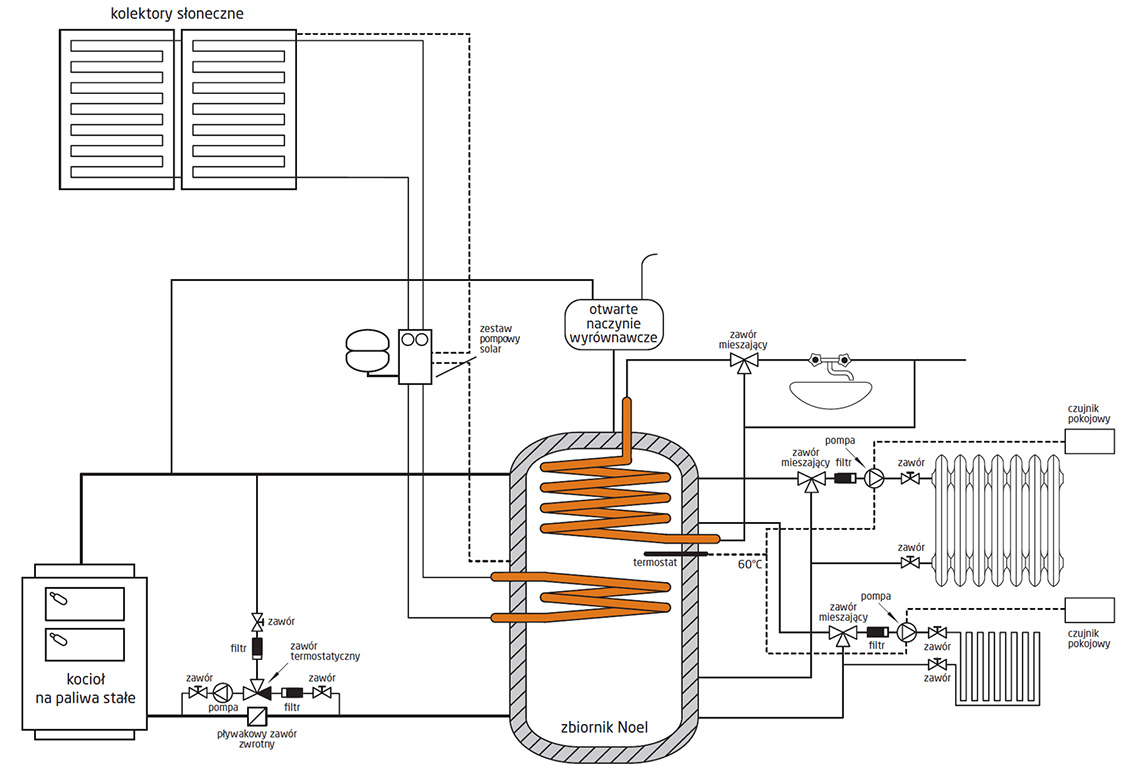

Connection Scheme for Solid Fuel Boiler and Solar Collectors

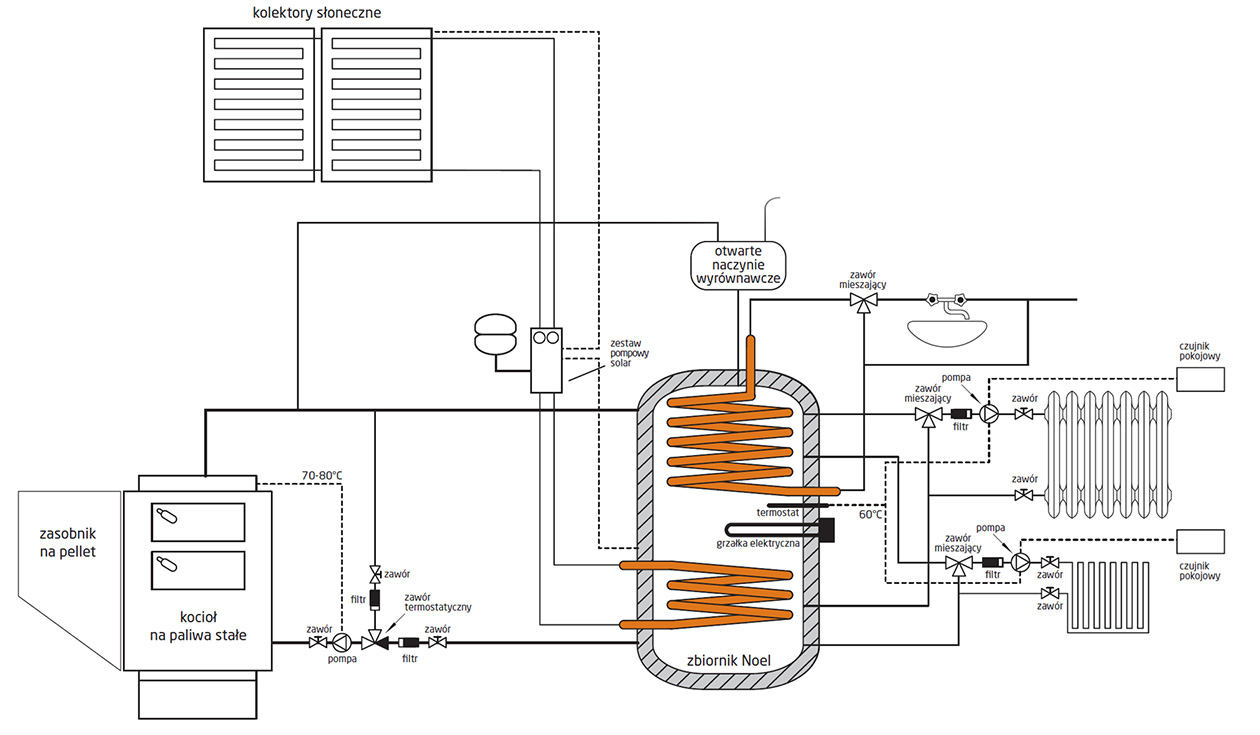

Scheme for Connecting a Solid Fuel Boiler and Solar Collectors

The above diagrams are simplified and do not replace the installation project.

They serve only as auxiliary conceptual designs helpful in developing the project. The diagrams do not include necessary protective and regulatory elements. Protections should be selected in accordance with applicable regulations. Connection of heating devices and fittings should be done according to the manufacturers’ recommendations. Pipe diameters, fittings used, and their connection methods should be adapted to the required flow rates of the heating medium provided in the instructions. If you need help with connecting the Noel tank, please contact our technical department.